Kinetic Metallization: Gas Turbine Engine Coatings

KM-CrAlY Characteristics

- Near Zero Porosity

- High Adhesion Strength

- High Oxidation Resistance

- Low Thermal Flux

High Bond Strength

- No Segregation

-

KM vs. Thermal Spray

-

Increased Thermal Barrier Uniformity

- Increased Coating Durability

- Reduced Oxidation

- Lower Equipment Cost

MCrAlY Gas Turbine Engine Coatings

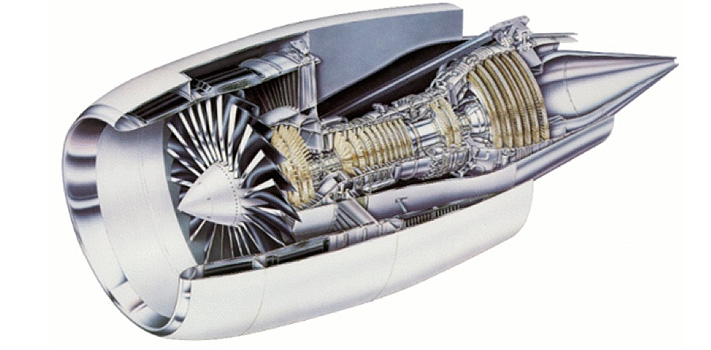

Higher turbine combustion temperatures are desirable for increased engine efficiency and environmental reasons (reduction in pollutant emissions, particularly NOx). High temperatures also place severe demands on the physical and chemical properties of the desired basic materials used in turbine fabrication.

Operating temperatures of gas turbine components are limited by the high temperature operating properties of the component materials. Thermal barrier coatings (TBCs) are used in order to reduce heat flow into the components, which prevents structural components from overheating and increases operating temperatures. Thermal barrier coatings are typically comprised of an insulating ceramic layer which is bonded to an MCrAlY coating which is resistant to oxidation. These thermal barriers usually fail as a result of a loss of ceramic due to impact, oxidation, or spallation under thermal cycling.

The Kinetic Metallization™ process’ edge in applying MCrAlY (M = Co, Ni, or Co/Ni) lies in its ability to deposit completely dense coatings and a secure metallurgical bond without having to employ a high-temperature heat treatment in a vacuum. Additionally, Inovati’s low temperature deposition process reduces precipitation and segregation of the coating constituents, which results in a more homogeneous and durable protective surface. KM minimizes the need for masking due to being a near-line-of-sight process, which saves labor and increases throughput. The KM process does not use hazardous or flammable gases, only inert helium gas.

Kinetic Metallization MCrAlY coatings are superior in quality to those produced by HVOF and LPPS in that KM coatings are subject to minimal oxidation during deposition, while at the same time bypassing the need for the expensive processes and equipment required by these other coating methods. Kinetic Metallization is being used to coat critical surfaces such as rocket nozzles because of its superior properties.